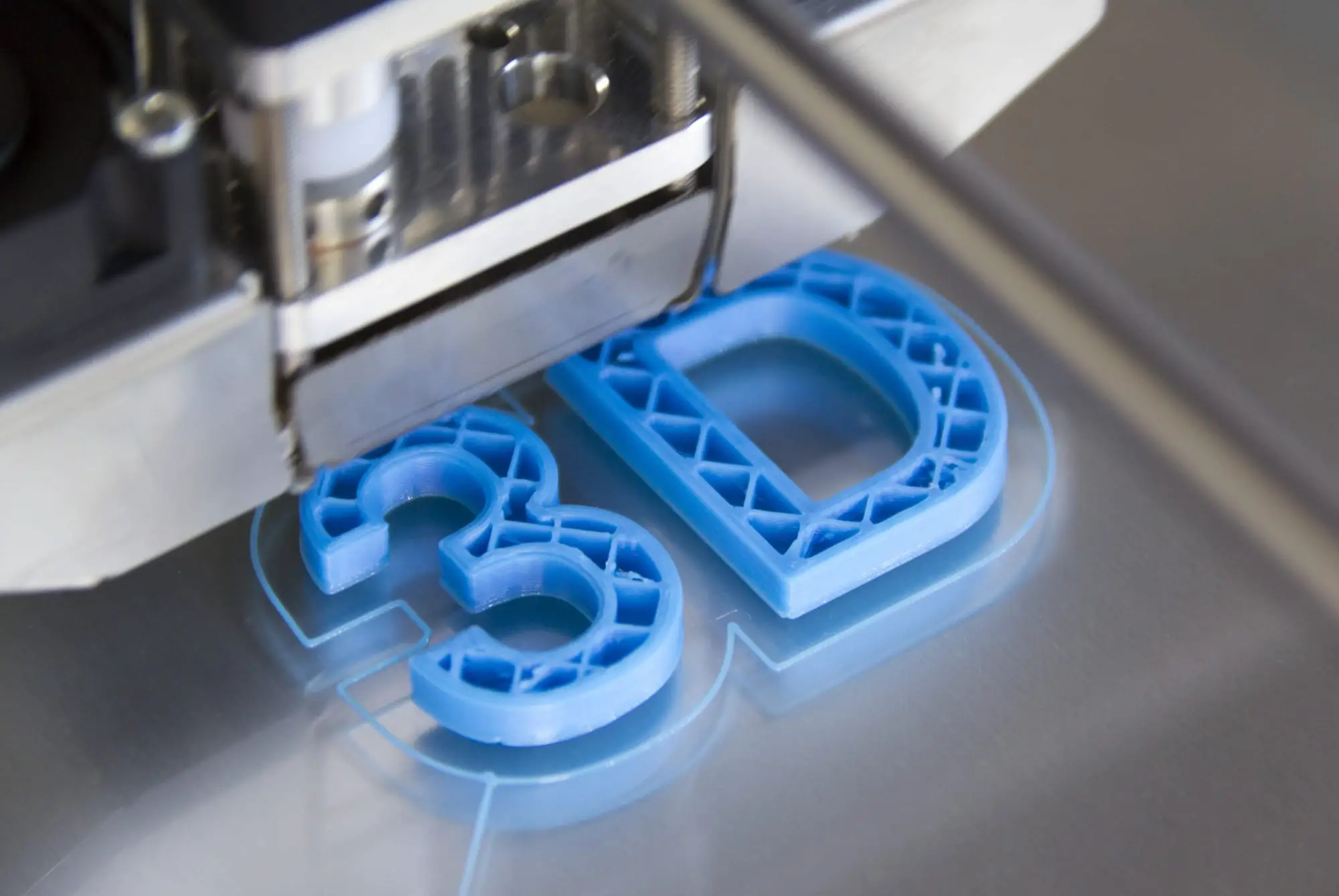

In the realm of modern innovation, 3D printing technology stands as a symbol of transformation. What was once considered a futuristic concept has become an integral part of various industries, pushing the boundaries of design, manufacturing, and creativity. From creating intricate prototypes to crafting customized products, 3D printing has evolved into a versatile tool that bridges the gap between virtual designs and physical reality.

The Genesis of 3D Printing

The roots of 3D printing can be traced back to the 1980s when it emerged as a revolutionary concept. Often referred to as “additive manufacturing,” 3D printing involves the layer-by-layer deposition of material to construct three-dimensional objects based on digital designs. This departure from traditional subtractive manufacturing methods has unlocked a world of possibilities.

Applications Across Industries

The applications of 3D printing have transcended niche fields, infiltrating industries with transformative solutions. In healthcare, it has enabled the creation of patient-specific implants, prosthetics, and even human tissue. Aerospace engineers harness its capabilities to fabricate lightweight yet robust components, optimizing aircraft performance. The automotive industry uses 3D printing for rapid prototyping and manufacturing intricate parts that were once thought to be infeasible.

Art, Fashion, and Architecture

Beyond industrial applications, 3D printing has become an artistic canvas, allowing creators to materialize their imaginative visions. Artists sculpt intricate sculptures, fashion designers craft avant-garde garments, and architects construct intricate models that visualize future cityscapes. The malleability of materials and the precision of printing have shattered creative constraints.

Material Advancements

The progression of 3D printing technology is inseparable from the development of novel materials. From plastics and metals to ceramics and even food, a wide array of materials can now be utilized for printing. Biocompatible materials have revolutionized medical applications, enabling the production of implants that integrate seamlessly with the human body.

Challenges and Future Outlook

While 3D printing technology continues to make strides, challenges remain. Speed, scalability, and the cost-effectiveness of production are areas of ongoing research. Furthermore, ensuring the ethical use of 3D printing in fields like weaponry demands careful consideration.

Looking ahead, experts predict that 3D printing will continue to disrupt traditional manufacturing methods. The emergence of 4D printing, where printed objects can change shape or function over time, presents yet another leap forward. As technology advances and materials become more diverse, the only limit to what can be printed seems to be the bounds of human imagination.

Conclusion

From pixels to print, 3D printing technology has transformed how we conceptualize, design, and produce objects. Its influence spans industries, sparking innovation, and redefining creativity. As researchers, engineers, and artists continue to push its boundaries, the journey of 3D printing evolves, offering glimpses into a future where the virtual and the physical seamlessly merge.